Do you know how an air conditioner or a refrigerator can cool down the air easily when the ambient temperature is so high?

If not, you would never understand the full function of these cooling appliances. As a result, you may even end up getting the wrong product. Owing to this reason, we have taken it upon ourselves to make you more aware of the cooling mechanism of the appliances- the compressors.

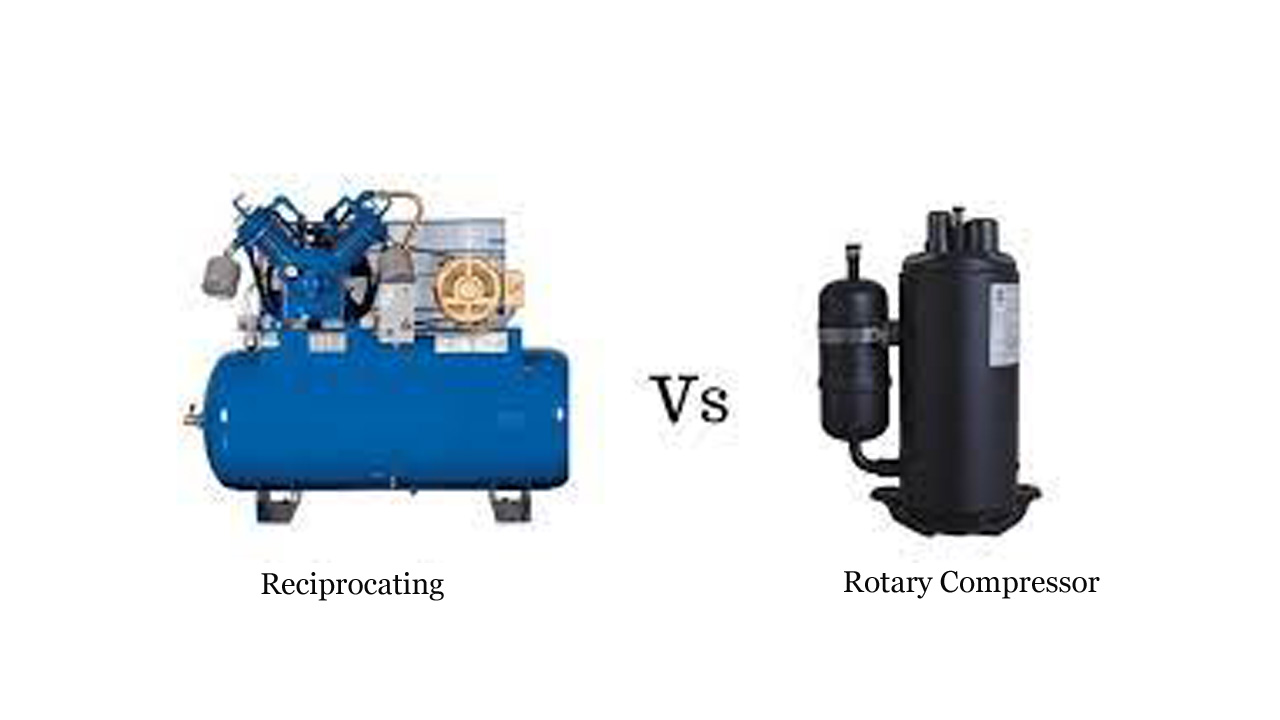

In the below article, we will talk about the working of a compressor. But our main highlight will be the presentation of a comparative study between reciprocating and rotary compressors. This will give you a complete idea about the compressing technology and help you buy the best appliance.

Reciprocating Vs Rotary Compressor

| Reciprocating compressors | Rotary compressors |

| Normal DC motors are used in these compressors. | Only BLDC motors are used in rotary compressors. |

| Energy consumption is constant and always at the highest level for the entire time, the appliance is on. | Energy consumption is varied as per the load, and hence much less. |

| Present for compressing air or any other fluid with high pressure | Can compress fluids with low to medium pressure value |

| Much cheaper in construction due to the use of basic elements | Costlier construction is required to include multiple advanced technologies |

| The efficiency of reciprocating compressors is less | The efficiency of the rotary compressors is much more |

What is a compressor, and what is its function?

The evaporator supplies the gaseous fluid or refrigerant to the compressor in any refrigeration unit. Its main function is to increase pressure and reduce the volume of the gas. The compressor’s work is based on Boyle’s and Charle’s law of gases.

According to Boyle’s law, the pressure of a gas is indirectly proportional to its volume at a constant temperature. Therefore, high pressure is applied when the gas enters the compression unit, reducing the volume. However, based on Charle’s law, volume is directly proportional to temperature. Therefore, once the compressor reduces the refrigerant’s volume, the temperature automatically reduces based on the appliance’s settings.

What are the two main types of compressors used in cooling appliances?

Even though several types of compressors are used in refrigeration units, the two most important categories are reciprocating and rotary compressors.

- In the reciprocating compressors, a piston compresses the gaseous fluid and further reduces the temperature.

- On the contrary, the rotary compressors will rotate about an axle and generate power to compress the gases and, in turn, change the temperature.

Working of rotary and reciprocating compressors

Now that you know the basics of rotary and reciprocating compressors, it’s time to study their working and structural construction.

1. Reciprocating compressors

In the reciprocating compressor, a piston moves to and fro in a swinging motion within the cylindrical structure. Its working is described in the following steps:

- There is an electric motor that starts working once the power is on. The piston connected with the shaft to complete a 180-degrees rotation as the motor turns.

- Since AC is supplied, the shaft is moved in and out of phase, causing the piston to rotate to and fro.

- This piston movement creates extremely low pressure in the compression chamber, causing the high-pressure air outside to flow into it.

- The suction activity of the compression cylinder is controlled using the suction value.

- Once the piston starts moving in the opposite direction, the air pressure inside the chamber and outside becomes equal, closing the valve.

2. Rotary compressors

In a rotary compressor, a single or dual rotor is present. They move around the axle and help compress the air flowing through the inlet. It can understand its function clearly from the below-mentioned facts.

- On switching the appliance, it automatically starts the BLDC motor. Due to this motor, which is fed into the rotor.

- High volume is flown through the chamber from the inlet, where the rotor has already started spinning around its axle.

- As it moves, the air flowing inside is compressed, and the volume gets reduced.

- The compressed air is then made to flow in the cooling unit, where the temperature is lowered as per the requirement.

Pros and cons of Reciprocating compressors

Pros

- It is the cheapest form of any other compressor used in the refrigeration unit.

- As no complex part is present in the compressor, it does not require much maintenance.

- In areas where the pressure is high, the reciprocating compressor is more suitable.

Cons

- The reciprocating compression units are bulky in terms of size and quite heavy.

- Noise generated at the time of compressing the air is too high.

- When the compressed air is discharged from the cylinder, its temperature rises.

Pros and cons of Rotary compressors

Pros

- The noise produced by the rotary compressors is much less, and hence, the appliance can work silently.

- The cooling efficiency of this compressor style is much better than the reciprocating compressors.

- The energy consumption of the rotary compression unit is low and more efficient.

Cons

- A rotary compressor needs high maintenance.

- The rotary compressors are costly since they are made from complex and advanced technologies.

Conclusion

This article has explained the basic points you need to remember about a compressor and its two major types. Based on this preliminary explanation, you can easily decide whether the rotary compressor will be ideal for your requirements or the reciprocating one.